Robert Aebi GmbH, Achstetten, Germany

All relevant item data from Microsoft Dynamics AXI resides in the Hänel MP 14 N lift controller

Robert Aebi GmbH supplies construction and agricultural machinery to regions in Southern Germany. For example, the company offers the complete range of Volvo earthmoving equipment.

Six different service centers are supplied with spare parts from the central warehouse in Laupheim. A Hänel Lean-Lift® is the intralogistics solution in operation at this site. The Hänel Lean-Lift® is integrated in the shipping department. This streamlines routing and speeds up the picking process.

Easy integration in the enterprise network

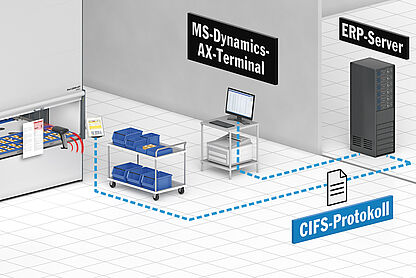

For all of its resource planning the company relies on Microsoft Dynamics AX. The Hänel Lean-Lift® is linked up to the enterprise network and receives item data and pick lists from the ERP system via CIFS protocol.

Thanks to integrated article pool management, all relevant item data from Microsoft Dynamics AX also resides in the lift controller. When a job order is started with the barcode scanner at the lift, the Hänel system automatically brings the requisite items to the access point for retrieval.

All items are neatly organized on the Hänel multifunction containers for maximum transparency and space savings. The Hänel compartment and sub-level indicators show precisely where spare parts are located on the container to ensure error-free retrieval.

Maximum ease of use and functionality with the touchscreen

The 12-inch touchscreen of the Hänel MP 14 N controller displays the item number as well as the quantity to be picked. When employees confirm the pick transaction on the controller, the storage lift then brings the next requisite item to the access point.

When all of the items on the pick list have been retrieved, the job is closed on the controller. When job orders are sent to the Hänel Lean-Lift®, inventory stock levels are automatically updated in Microsoft Dynamics.

Every square meter is optimally used – that’s the essence of efficiency

The vertical lift is 29.52 ft/9 m in height and fully utilizes the space available – from floor to ceiling – to provide maximum storage capacity within a minimum footprint. The system has 82 containers for the safe and secure storage of more than 20 tons of spare parts.

The height-optimized storage ensures that even the most diverse parts can be stored compactly for high cost-effectiveness.

Energy-efficient picking coupled with increased picking performance

The Hänel Lean-Lift® with EcoDrive® is equipped with a frequency converter to recover energy. During the extractor’s downward movement, electrical energy is returned to the power supply system. In addition to better picking performance and the expansion of storage capacity, Robert Aebi GmbH was also focused on improving workplace ergonomics. Hänel vertical lift technology delivers a number of obvious benefits not possible with conventional high-bay storage solutions: improved employee safety, lower risk of accidents and dramatically improved warehouse working conditions.

Robert Aebi GmbH is very satisfied with the easy-to-operate Hänel Lean-Lift® – not to mention the outstanding service provided by Hänel!

"The Hänel Lean-Lift® – a decision for the future!"

Ulrich Heim,

Head of Parts Department