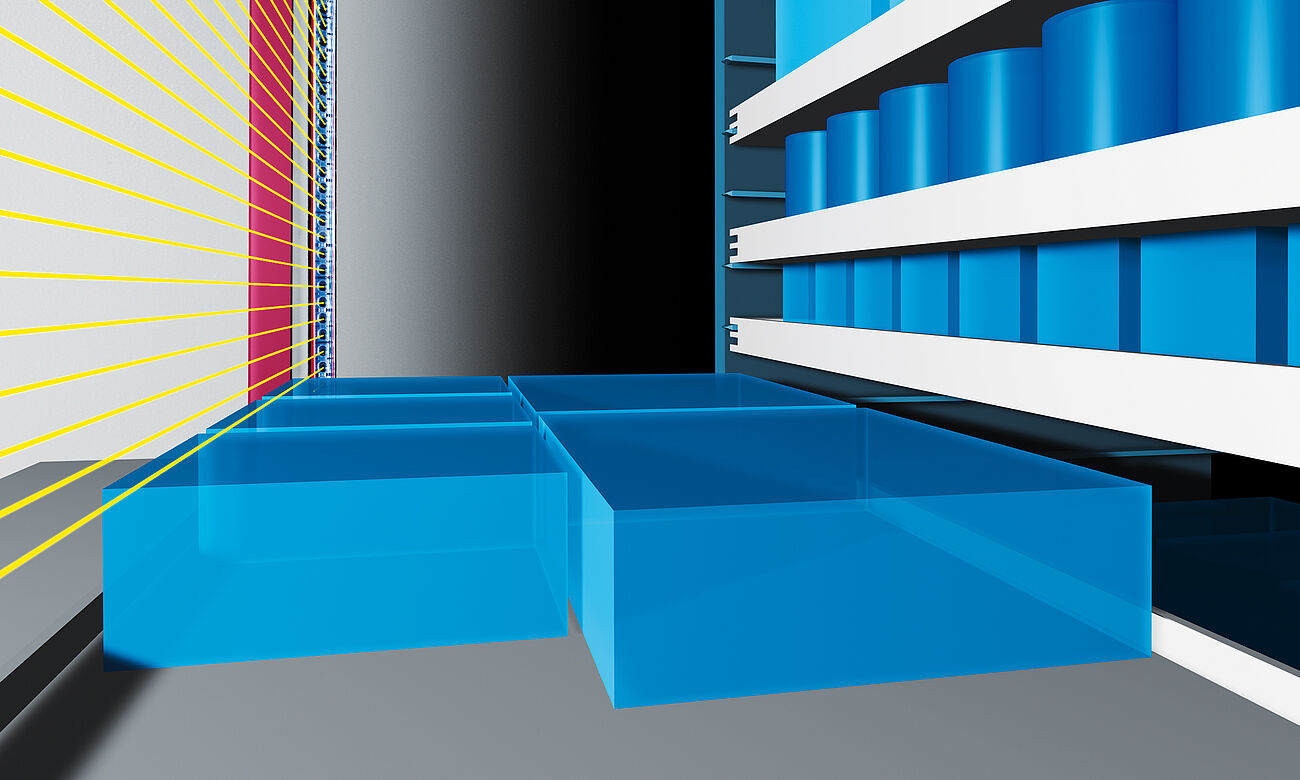

Hänel Multi-Space® Vertical Lift Module

Storage principle

The Hänel Multi-Space® principle:

With simultaneous horizontal and vertical movement, the articles are stowed away in the Hänel Multi-Space® by the quickest route.

- Extractor of lightweight construction

dimensionally stable and scalable - 4-chain technology

for optimum guidance and precise positioning of the extractor - Integrated slot profile

for height-optimized storage of the containers - Multifunction containers

from 551 lbs/250 kg to 1,102 lbs/500 kg payload - Light-barrier curtains

ensure maximum safety for operating personnel - High-speed door

safeguarding the access point at the rear - Height-detection sensors

to determine the height of stored articles - Inspection doors

positioned conveniently and safely on both sides - Hänel microprocessor control unit

positioned ergonomically at the side - Interior lighting

integrated lighting unit in each access point (optional) - Switch box

the electronics are housed in a clear layout - Environmentally friendly powder-based finish

gives 50 % higher scuff resistance - Soft start control with frequency converter

The Hänel Multi-Space®

Maximum flexibility

With the rollout of the Multi-Space®, Hänel optimizes the principle of 3-axis storage systems. In addition to the many benefits of Hänel’s Lean-Lift® technology, the Hänel Multi-Space® offers maximum flexibility, speed, and space utilization.

Maximum flexibility

Thanks to its cutting-edge technology, Hänel is able to offer a 3-axis storage system that is over 9 m wide. The Hänel Multi-Space® can even vary its width and height to meet later needs – a new feature from Hänel! Even the number of access points is variable and can be altered at any time. Along with the different container widths and depths, this results in the most versatile of combination possibilities.

Optimum space utilization

The variable positioning of the access openings makes optimal integration into already existing storerooms possible. Previously inaccessible areas can be integrated into a storage concept without difficulty. And the Hänel slot profile combined with the Hanel multifunction containers are the ideal prerequisites for compact, heightoptimized storage.

Time saved

No waiting – one operator can perform order picking at two access points! At units with two access openings, users can retrieve at one and store at the other simultaneously!

The right decision

If you want to improve your intralogistics concept and reduce costs, you should talk to the specialists at Hänel first. They will work with you to develop your own ‘tailor-made intralogistics concept’.

The Hänel Multi-Space offers optimum space utilization, short distances between the access points and many varied combination possibilities

The pluses

- Modular scalability with the use of additional storage units (payload up to 40 tons per unit)!

- Unique extractor design in state-of-the-art lightweight construction (as used in bridge engineering) ensures maximum stability.

- The Hänel Multi-Space® offers modular scalability in height and width – up to a total width of over 29 ft / 9 meters.

- Variable container widths, different payload capacities and the Hänel multiple pitch ensure the optimal solution for any challenge to compact storage.