DD Kabelkonfektion Dropulic, Wilhelm-Leuschner-Straße 1, 72636 Frickenhausen, Germany

Ten Hänel storage lifts provide the perfect all-around solution

Tool storage, materials storage, production and shipping storage – two Hänel Lean-Lifts® and eight Hänel Rotomat® storage lifts handle the most diverse needs

DD Kabelkonfektion Dropulic is an innovative supplier of high-quality products for cable processing and cable assembly. The company’s site in Frickenhausen utilizes numerous Hänel storage solutions in the 2,300 m2/24.76 ft production and storage areas to ensure perfect order processing.

Direct material provision for an efficient workflow

The company’s machinery and outgoing goods department are located on the ground floor. Two Hänel Rotomat® storage lifts are deployed in the immediate vicinity of the production. The ceiling-high lifts provide cables for the processing on the adjacent machines while the finished cables are stored for shipment to customers. The employees can quickly access the stored goods by simply entering the article number. The cables stored in the lift are transferred to the removal area of the Hänel Rotomat® storage lift when requested. The lifts also contain a wide range of items are organized in boxes. These can be effortlessly removed thanks to the rollers integrated into the worktop. This ergonomic provision simplifies handling, especially for heavy cables with a large cross-section.

Flexible and clear tool organization in the Hänel Rotomat® storage lift directly on the production lines

An additional Hänel Rotomat® storage lift designed for stand-alone operation centrally supplies the entire production with the required press tools and test blanks. The expensive and delicate equipment is stored safely in the lift, where it is protected against external influences.

When an adjacent workstation is prepared for a new assembly, all required special tools can be requested from the lift via the MP0N lift controller. The extensive partitioning options in the Hänel Rotomat® storage lift are used to combine compartments with boxes and drawers combined in a carousel. This provides dust-free storage space for even the most diverse parts.

By utilizing the full ceiling height, the Hänel Rotomat® storage lift only requires a very small footprint. As a result, the facility was effortlessly expanded to include a directly adjacent Rotomat® small parts warehouse, ensuring short walking distances.

Central material warehouse for production and on-time delivery

DD Kabelkonfektion Dropulic guarantees short delivery times by stocking numerous raw and finished parts. In addition, semifinished and finished parts can be stocked at the customer’s request for delivery according to the production schedule. This service requires the right warehouse logistics. That is why central materials warehouse is equipped with two Hänel Rotomat® storage lifts and two Hänel Lean-Lifts®. Different components, small parts and connectors are stored here and compiled for processing in production in accordance with the order.

Integrated warehouse management combined with ERPsupported customer orders

The Hänel storage lifts are controlled by the MP 12 N compact controller featuring integrated warehouse management. This enables direct access to the storage locations, article numbers and storage quantities via the controller during picking.

Customer orders are generated via the ERP system and delivered as a picking order. Entering the article number on the lift control automatically transports the respective order item to the removal point. The quantity taken is confirmed and the item is also documented in the ERP system.

Once an order has been compiled, it is transferred to the production department for further processing. In collaboration with Hänel’s specialists, the company is already working on linking Hänel’s lift controls directly to the ERP system.

Subsequent expansion of storage capacity through relocation

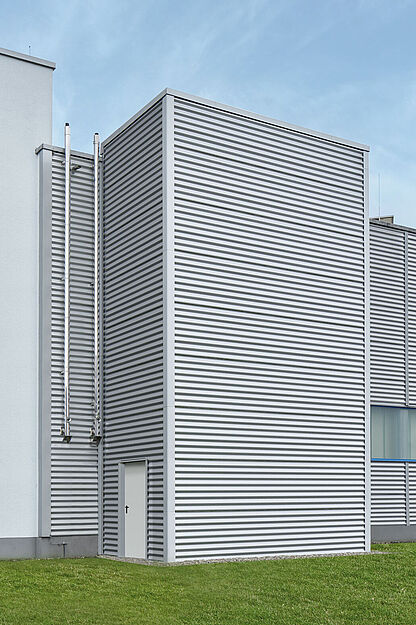

The company’s steady growth has also increased its need for storage space. Adding an eight-meter high Hänel Lean-Lift® to the outer shell of the company building enabled DD Kabelkonfektion Dropulic to enormously expand its storage capacity.

Working in close collaboration with Hänel’s experts, the company has successfully created the optimum storage solution for all of its logistics requirements. Ten Hänel warehouse lifts located around the facility now effectively support employees during their daily work. The Hänel lifts offer enormous space savings in locations where space is at a premium, thus enabling production capacities to be increased in the future.

DD Kabelkonfektion Dropulic has relied on Hänel’s innovative storage solutions for more than 20 years. In addition to the quick access and flexible application options, Hänel’s proven quality was a key argument in favor of the successive addition of further storage lifts.

"The ten storage lifts from Hänel enable us to make optimum use of every square centimeter of our warehouse while simultaneously simplifying the handling of tools and materials – efficiency, convenience and safety in perfect harmony."

Andreas Lutz,

Authorized signatory