Drive system

Machine tool component storage

State-of-the-art intralogistics with Hänel Lean-Lifts® and viad@t

Vertical lift modules condense valuable storage space

With the constantly growing range of articles handled by TOX® PRESSOTECHNIK, the capacity of their manually operated store and their automated tray warehouse was virtually exhausted. Michael Laub, Head of Production at the successful mid-sized company says: “In addition to that, we were set to lose the support for the warehouse management software of our old tray store which another provider built. So together with the two specialists in efficient automated storage systems – viastore systems and Hänel Büro- und Lagersysteme – we installed a solution with which we could save valuable space and respond flexibly to future requirements.”

First of all the experts replaced the manually operated store with three Hänel Lean-Lifts® . Because of the high total payload of each individual Lean-Lift® (up to 60 tons), these were installed in the basement. The access points were located on the ground floor. This means the 14 meter high storagelifts use the full height of both the basement

and the warehouse. This has reduced the overall storage area from about 450 square meters to the footprint of the lifts, which is 21 square meters, thus freeing up valuable floor space.

Future-oriented storage systems

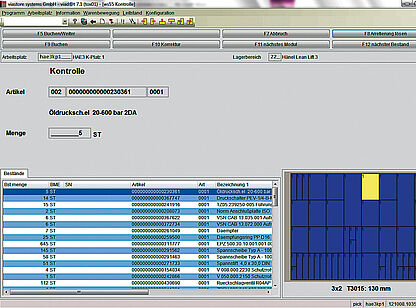

viastore systems integrated the storage units into the warehouse management system viad@t WMS that was newly introduced at TOX®. This expandable and flexible software is integrated into the SAP ERP system via a standard interface.

The time-consuming “man to goods” method of the manually operated warehouse has now been replaced by “goods to man” picking at the Lean-Lift®. As a result, picking errors have been reduced significantly. The new WMS in conjunction with the high-speed Hänel Lean-Lifts® enables high transparency along with quick and reliable access to the articles.

Production manager Michael Laub points out: “The modular storage lifts from Hänel and the warehouse management system from viastore systems can be expanded at any time. Moreover, viastore systems has also integrated our tray warehouse into viad@t. With this end-to-end solution we can respond flexibly to changing conditions in the future. Moreover, the reliability and durability of the components along with the 24-hour service on more than 300 days a year were decisive factors for us.”

The height-optimized storage strategy in the vertical lift modules from Hänel means that the storage space at TOX® PRESSOTECHNIK is condensed and used more efficiently. The TOX® employees can use the systems flexibly and process orders quickly. Integration of viad@t into SAP guarantees complete transparency.

The modular technology of viastore systems and Hänel Büro- und Lagersysteme also enables faster product deliveries, improved stock control, minimized pick errors, efficient order picking and therefore shorter lead times. Moreover, viad@tWMS allows the high-bay tray warehouse to have a future-oriented warehouse management system.