Small parts bin storage

Hänel Rotomat Vertical Carousel

Fierthbauer GmbH is part of a business organization that delivers systems to special vehicle manufacturers and engineering companies throughout Europe.

Fierthbauer operates a Hänel Rotomat® storage system in its shipping department to boost picking processes for small parts. By fully exploiting the warehouse height – from floor to ceiling – overall storage density was increased to provide maximum storage capacity within a minimum footprint.

The Hänel Rotomat® is based on the Ferris wheel principle and brings various kinds of stored items to the access point for fast, safe and ergonomic retrieval. Large numbers of diverse small parts are stored in bins which are neatly organized on the multifunction carriers of the Hänel system. One single Hänel Rotomat® industrial storage system can hold more than eight tons of material.

Storage positions are allocated by the Hänel MP 12 N controller

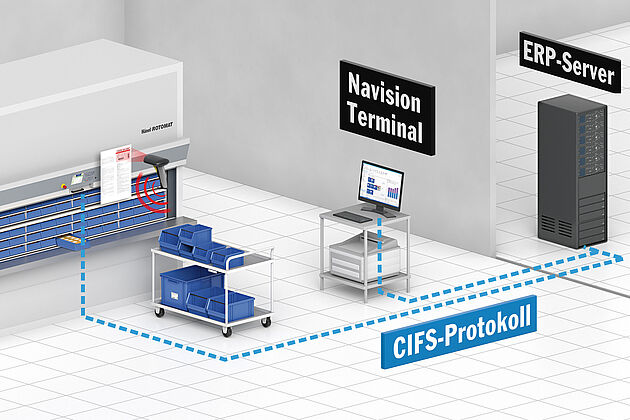

Thanks to the extreme flexibility of Hänel controllers, the lift system was seamlessly integrated in the customer’s existing network. The controllers are very easy to use and have a wide range of functions. All job and item information is sent via CIFS from the customer’s Navision ERP solution directly to the MP 12 N controller. During putaway processes, the MP 12 N supports the search for unoccupied storage positions.

Transaction data is sent to Navision by the minute

Employees start the picking process by scanning the job barcodes directly at the lift access point. Based on optimized routing, the multifunction carriers holding the requested items are sequentially brought to the access point for retrieval.

Users can then pick the items from the storage system at an ergonomic height. Quantities and item numbers are displayed on the Hänel MP 12 N microprocessor controller.

When the user confirms retrieval on the control unit, the storage system automatically brings the next requisite item to the access point – this process continues until all of the items on the pick list have been retrieved.

Transaction data is sent to Navision every minute via the transaction journal. Inventory status is constantly monitored and updated by the Hänel inventory module.

The goods-to-man principle improves ergonomics – and users do not have to walk around looking for requested items. The Hänel compartment and sub-level indicators, which are integrated in the work counter, help users identify storage positions. This speeds up the picking process and considerably reduces picking errors.

The seven-fold increase in storage density, and the doubling of overall picks, are among the many benefits delivered by the Hänel Rotomat® in the shipping department at Fierthbauer in Esslingen-Zell.

"The Hänel Rotomat® has enabled us to expand our warehouse floor space by a factor of seven. The number of picks has more than doubled, and errors have been reduced dramatically. The linkup to Navision was fast and posed no problems."

Torsten Brandstetter,

Head of Production and Logistics