HEDELIUS Maschinenfabrik GmbH, Sandstraße 11, 49716 Meppen, Germany

Reliable express delivery of spare parts with 14 automated storage systems from Hänel

Reliable on-site service and rapid processing of spare parts requests – eight Hänel Lean-Lifts® and six Hänel Rotomat® storage lifts provide quick access to 7,500 spare parts

HEDELIUS Maschinenfabrik in Meppen develops and produces high-performance vertical CNC traveling column machining centers. Its customers include numerous renowned machine manufacturers and their suppliers from a wide range of industries. The company guarantees customers 95 % availability for its extensive range of machines. As part of this service, customers can submit spare parts requests to the service center or arrange appointments for on-site service directly via the machine.

The company’s central warehouse merges all of the orders from the service requests.

From here, spare parts are shipped to both customers and the company’s own service technicians are supplied with materials and tools.

Provision of special tools for rapid service

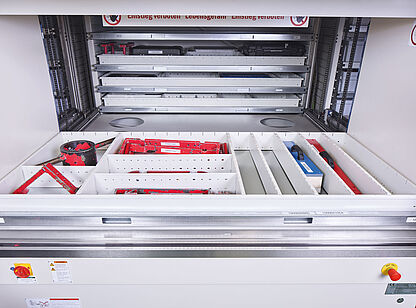

The service technicians carry numerous tools for repairs and inspections. Any special equipment needed for a particular machine is drawn from the tool storage. A network of six Hänel Lean-Lifts® stores numerous devices and special equipment for short-term provision to technicians. These sometimes large tools are often made up of multiple components or are stored in cases as a complete set. The flexibly divisible Hänel multi-function containers in the Hänel Lean-Lift® serve as the optimum organization and storage system.

Optimum organization of a wide range of part sizes using Hänel multifunctional containers

A total of eight Hänel Lean-Lifts® provide safe and height-optimized storage for the extensive special equipment as well as an extensive range of larger spare parts such as ball screw drives. With a load capacity of 250 kg/552.15 lbs per container, the Hänel multifunctional containers are the ideal storage when it comes to flexibly organizing components with widely differing sizes.

In addition to increasing picking performance and expanding storage capacity, HEDELIUS also focused on reducing travel times. Accordingly, all of the Hänel lifts are located directly at the shipping and packing station.

Hänel storage lifts also impress employees with their ergonomics and safety

Aside from the short walking distances, warehouse logisticians also benefit greatly from the ergonomic provision of the requested parts during the course of their daily work. After the container number has been entered on the Hänel Lean-Lift®, the stored goods are simply transferred from the clearly laid out lift picker to a picking cart without needing to use any further aids. The Hänel compartment and compartment display further supports users and shows the specific storage location on the container.

When picking small parts on the Hänel Rotomat® storage lift, the storage bins are pulled directly onto the worktop at an ergonomic height for easy storage and retrieval.

This efficient warehouse organization at the central HEDELIUS spare parts warehouse lays the foundation for express shipping of up to 50 individual shipments per day.

Hänel storage systems are durable and can be flexibly adapted to new logistics concepts

HEDELIUS commissioned the first Hänel lifts more than 20 years ago. Over the years, additional Hänel storage lifts have been added to continuously increase the storage capacity. The company’s logistics department has consistently evolved since then and the spare parts warehouse currently consists of eight Hänel Lean-Lifts® along with six Hänel Rotomat® storage lifts.

The conversion and combination of the old and new Hänel lifts took place at HEDELIUS in collaboration with Hänel to create sustainable storage solution designed for maximum performance and space usage.

Reliable Hänel intralogistics solutions have formed the backbone of effective work processes, the fastest response times and the highest customer satisfaction for decades.

"Hänel provides a convincing combination of fast and competent customer advice together with delivery reliability and the highest product quality. This is precisely what our customers also demand. When the cooperation goes so well from the outset, there is no reason to change it."

Reiner Korte,

Managing Director