Hänel heavy-duty systems - secure storage of heavy items and goods

Sturdy heavy-duty storage systems for extremely heavy payloads

Extremely heavy goods and payloads are kept in special heavy-duty storage systems. During pick and place operations, heavy-duty systems must withstand considerable stress and strain which is exerted by the extreme weight of the items in storage.

Hänel heavy-duty solutions - "goods to man" systems

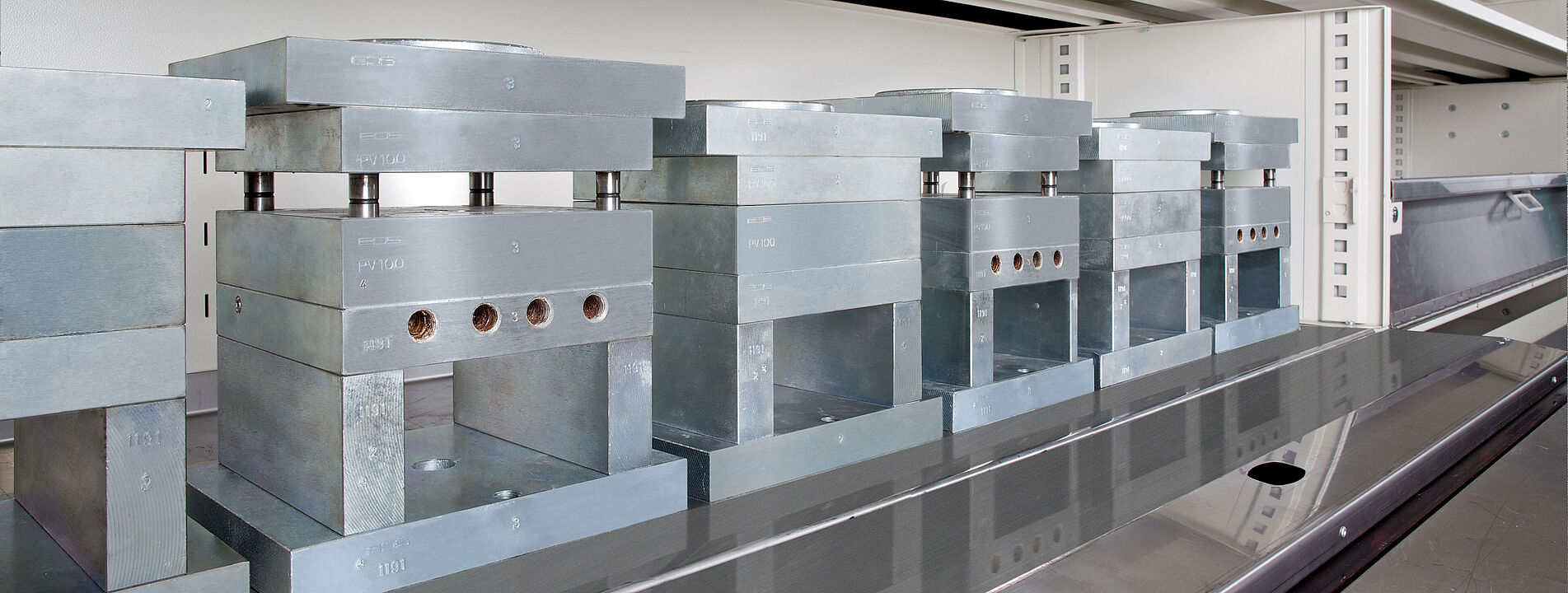

Heavy-duty storage systems usually function according to the "goods to man" principle. Unlike heavy-duty shelves, which must only carry the extreme weight of specific items, heavy-duty storage systems must also be equipped with electric motors, drive components such as chains and containers that are specially designed to withstand the forces exerted by extremely heavy payloads. Equipment needed for injection molding and tools used for steel pressing and stamping are usually stored in heavy-duty systems. This kind of tool storage demands a "goods to man" system which requires a large footprint because the extreme weight of the tools limits the height possible with vertical storage. An automated heavy-duty storage system can utilize the entire vertical space available within a building. Tools are automatically brought to the access point on request. Then these items can be moved to other areas using transport trolleys or suspended cranes.

The Hänel Lean-Lift® – the preferred choice

Hänel offers the heavy-duty version of the Hänel Lean-Lift® as an efficient storage solution for items of extreme weight. The system containers can carry payloads of up to 1,000 kg. The heavy-duty Hänel Lean-Lift® has a total load-bearing capacity of up to 60 tons. A heavy-duty version of the Hänel Rotomat® storage carousel is also available. The heavy-duty Rotomat® storage system is well-suited for specific applications with unusually heavy payloads.