Smart Picking

Optimized order picking with the Hänel storage systems

The use of web devices makes order picking with the Hänel Rotomat®, Lockomat®, Lean-Lift® and Multi-Space® easy and flexible

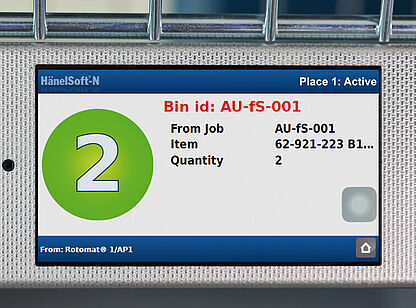

This future-centric and affordable order picking solution (Module N530) is based on HänelSoft®-N warehouse management software in conjunction with Module N205 (aggregated order module). This approach means that several orders can be combined in one aggregated picking operation. The picking process conducted at the Hänel lifts and in the warehouse rack area typically involves the use of a picking cart which carries a bin for each individual order. Commercially available web devices are attached to the bins on picking carts and show employees which bins are to be used for each pick operation. The web devices or barcode scanners are used to allocate the bins – this process is quick and easy. Allocation can be done automatically or manually.

The put-to-light display also shows the item number, order number, quantities on inventory, etc. directly on the bins positioned on the picking cart. Aggregated picking is conducted in parallel with the lift controller supported by the web device – this saves time and keeps routing short. Combining quantities during retrieval (one pick) is also possible. The total quantity of an article that is listed on different orders is retrieved with one pick and then split up on the picking cart. All data is centrally managed and booked in HänelSoft®-N. The use of commercially available web devices makes this solution very convenient, efficient and affordable.

Intelligent systems for high-speed picking!